1.Summarize of installation

Position of installation of the fan

The notices of choosing position as follows:

If the fan in the open air, it must has safeguard.

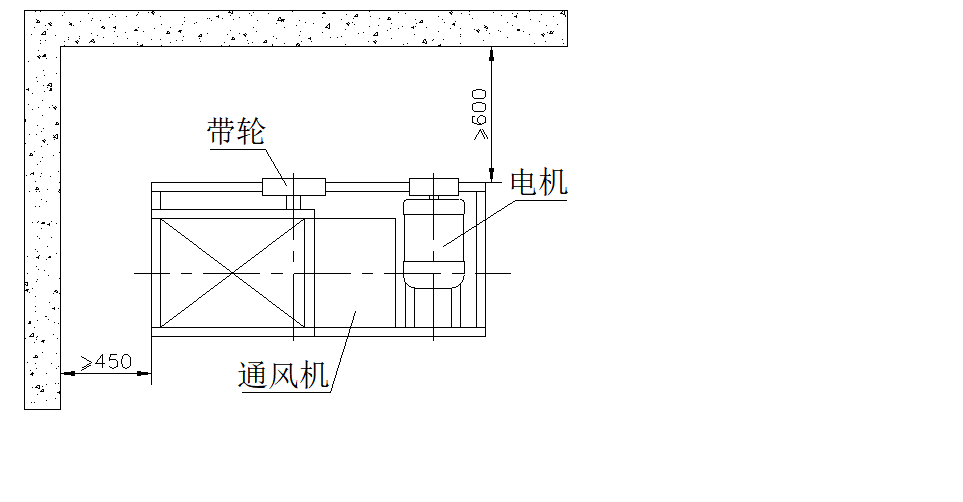

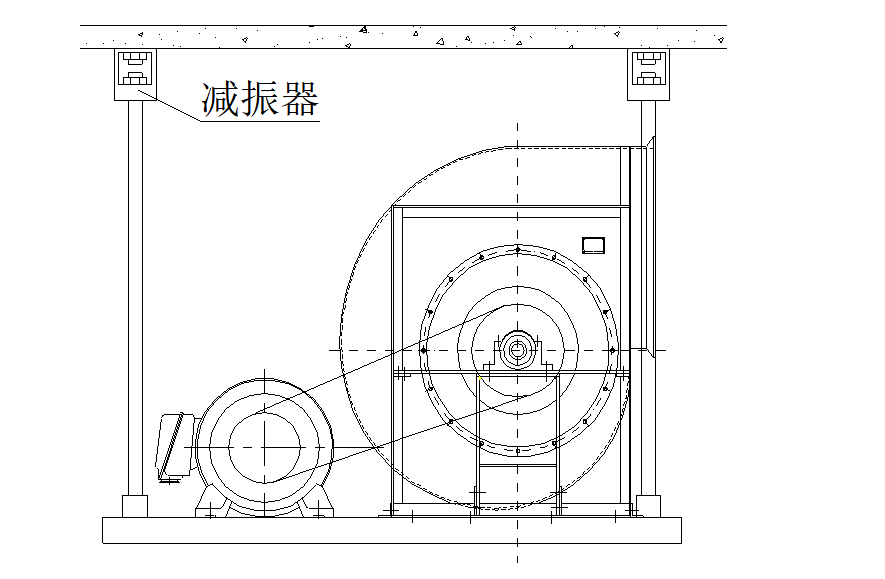

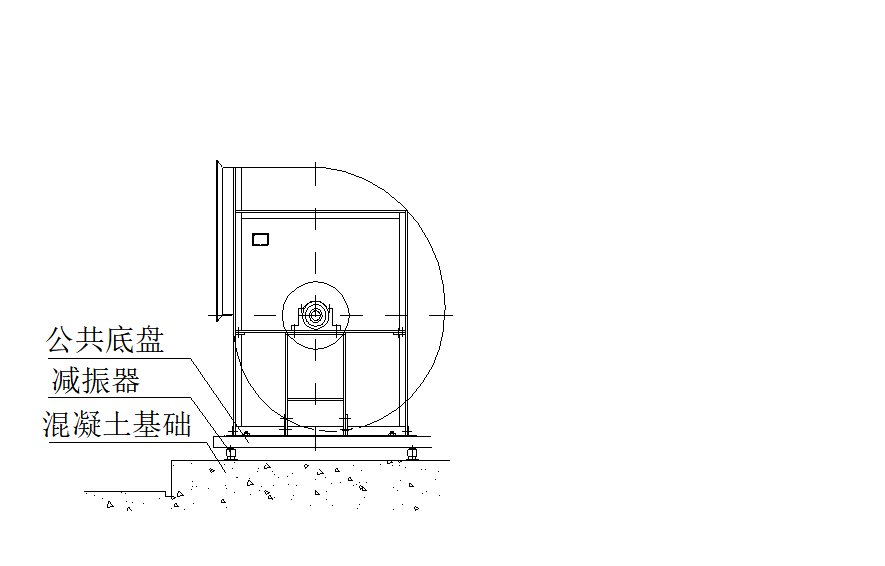

The fan should be installed in the location where is easy to manage and watch. See drawing 1.

Drawing 1

The location should be has solid basic.

Especially the fan will be installed on the overhead frame, the location hasn’t any factor of vibration must.

2.Demands of space

You should pay attention to estimate the acreage of installation as follows:

Don’t disturb other machine around it.

Examine and repair convenient.

There is enough space for take down impeller.

3.Methods and demands of installation

1.Be installed on the ground.

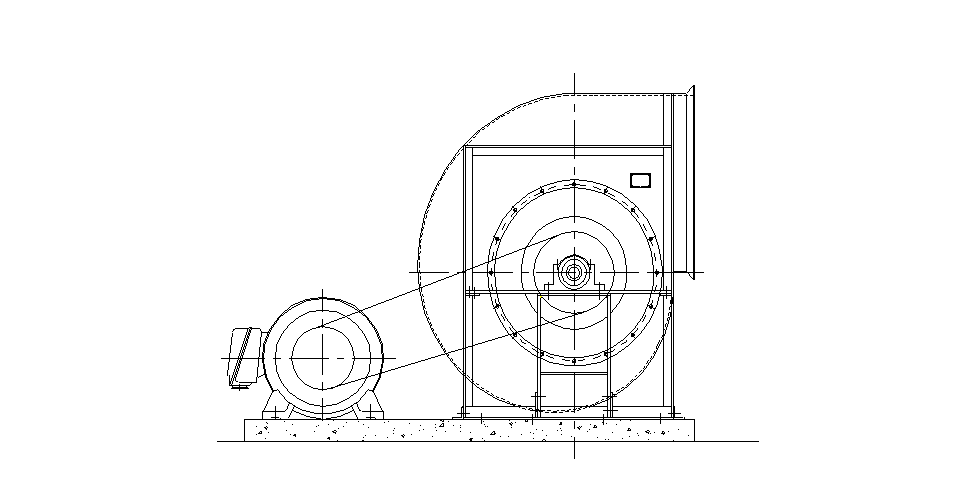

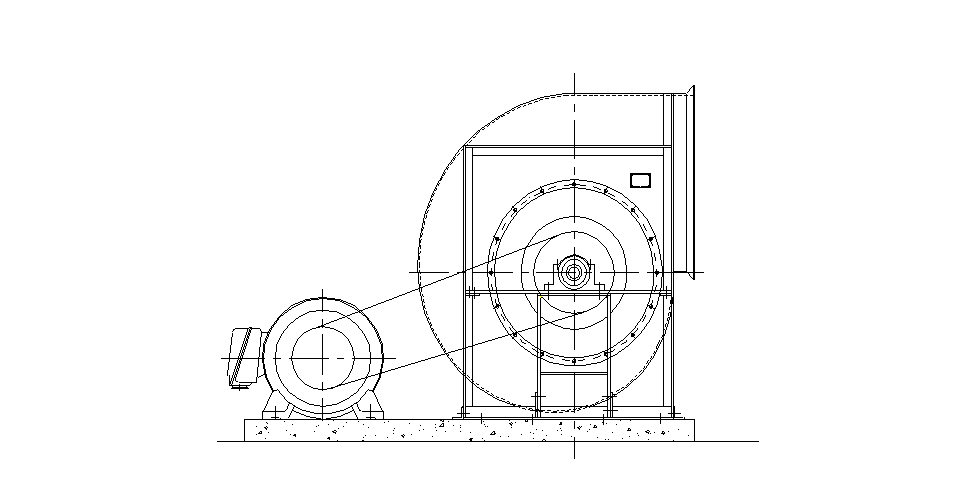

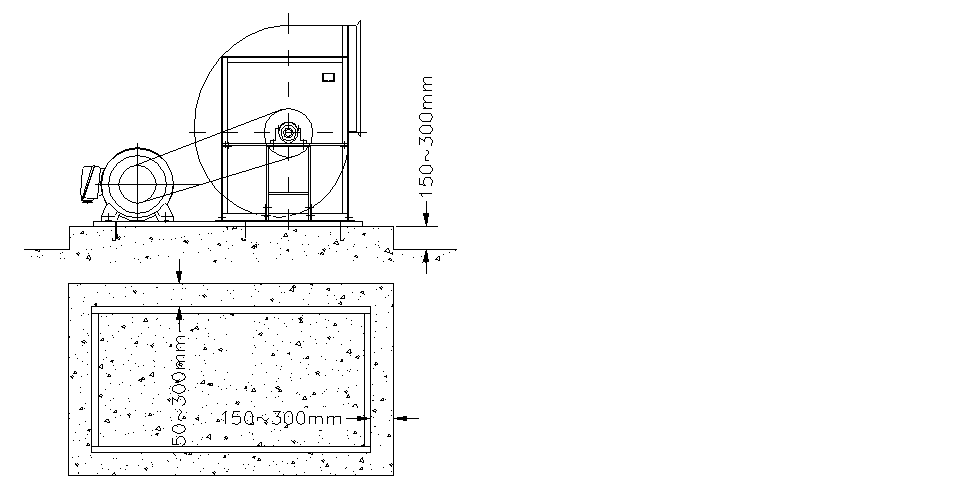

Fans are usually installed on the concrete bedrock except the fans are smaller with small type and motor power. Even so, you should pay attention to the intensity of basic. See drawing 2.

Drawing 2

2.Be installed on the hathpace.

You should pay attention to the angular rigidity and intensity of the installation area to avoid resonance, otherwise adopt measure of reinforce. See drawing 3A.

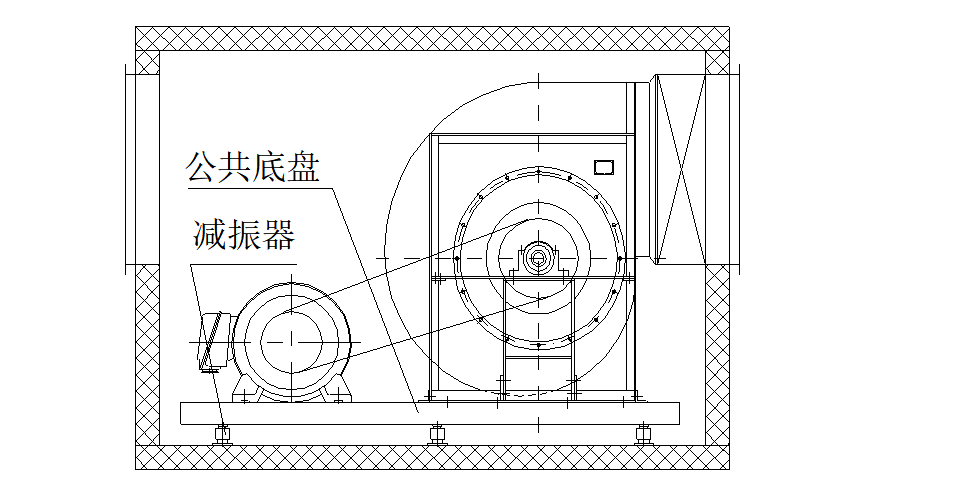

3.Be installed in the fan box.

In order to avoid libration which would be caused of lack in rigidity and intensity of the frame, you should pay attention to the intensity. Especially when use rubber or spring vibration damper, the fan and the motor would be installed on the same underpan. See drawing 3B.

Drawing 3A

Drawing 3B

Drawing 4A

Drawing 4B

4.Be hung on the ceiling

Small fans should be installed with bolts simply, (See drawing 4A). Medium-sized fans should be installed with weldments of frame, but then installed on the ground to the best of your abilities.

When exhaust fans should be installed on the wall, the wall must fastness.

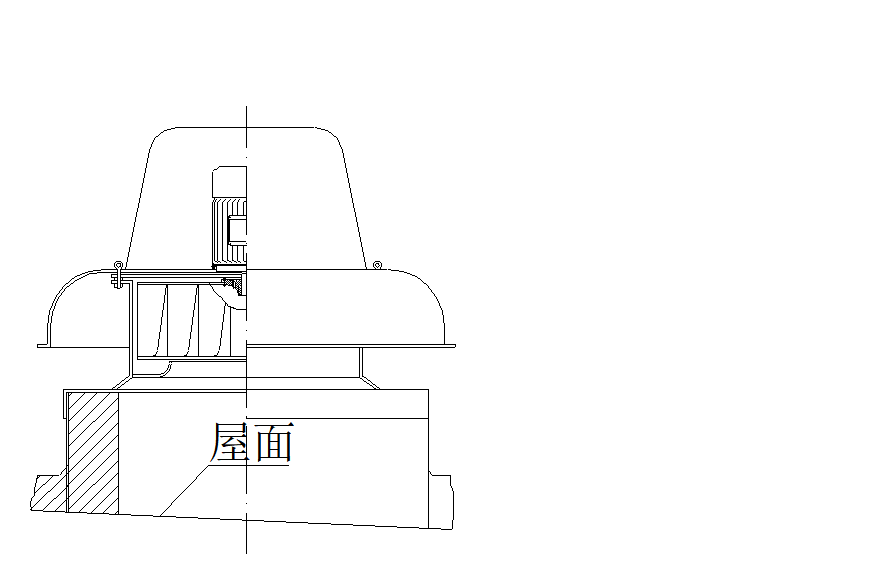

Be installed on the roof.

You should think about the effects from storm, rain and snow. See drawing 4B.

2.Basic

1.Concrete bedrock

The plane size of concrete bedrock is bigger 150~300mm than the size of fan border. The sizes of concrete bedrock for small fans take the minimum but its thickness is bigger than 150mm must and weight is bigger 5 ~10 multiples than the weight of total fan. See drawing 5

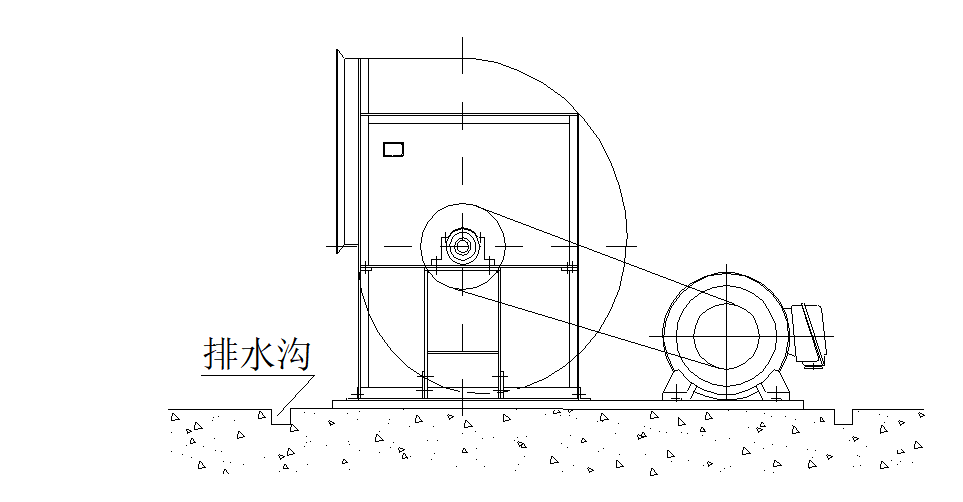

You should mount a drain for no water in the basic, and that it will not eroded. See drawing 6.

The surface of basic is smooth and trim, you should think about the holes for installing the bolts beforehand.

Drawing 5

Drawing 6

Regulate the basic surface and fan frame with gasket, then fixup after the basic come into contact with the gasket enough.

2.Shakeproof element

Shakeproof elements include gaskets, rubber, spring and so on. See drawing 7.

You’d better choose the correct shakeproof elements according to the weight and function frequency of the fan. If the fan runs in low speed or loads lightly, the shakeproof element can select rubber.

Drawing 7

3.Using of the shakeproof element

The underpan where has installed fan and motor has enough angular rigidity when you use the shakeproof element.

The basic is aclinic for the sake of all shakeproof elements support equal. If there’s anything under the frame, the fan would shaken unconventionally.

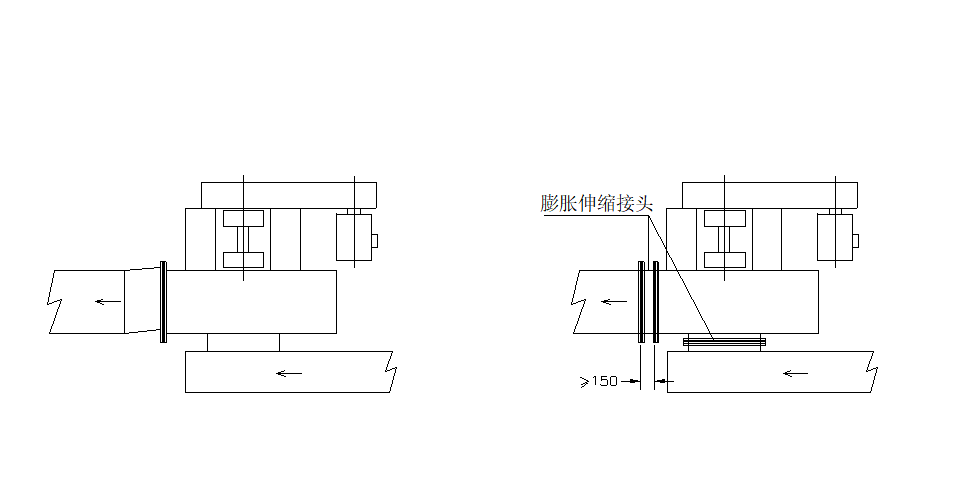

When use the shakeproof element, you must install flexible tie-in in the pipe joint of the fan.

The balance of impeller will be destroyed when dust or eyewinker cling to the impeller, in this case, use shakeproof element is not correct.

3.Transit, deposited, safekeeping

All the fans have checked out with center emendation, balance, running, then was qualified to leave factory, so the client must pay attention to abrade and distortion during transit.

1.Check the parts

Check the fans whether or not have damnification, distortion, consummate paint.

Check the parts and spare parts.

2.Hoist and transit

Please use the hook when transiting, perching and hoisting.

When hoisting fission casing and rotors, fill in with soft where the rigging and workpiece touched, especially the impeller and shaft. Otherwise will debase the precision of balancing, result in the fan shaken.

Pay attention to fix the rigging for the pulley and brass lubrication nipples are vulnerable.

The move of equipment brings large impulsive force of shaft, pulley and impeller, please advert it.

The move of equipment brings large impulsive force of shaft, pulley and impeller, please advert it.

During the keeping period, insist on twice jigger per month at least, 10 turns every time and stop at the point of over 180°. At the same time, pay attention to the degree of bearing lubrication. Secondly, some times of open and close the rotor such as adjustable door, if necessary, immit the lube in order to prevent rustiness.

To check the libricate after open the bearing cover if the fan haven’t run for a long time, add the new lube if necessary.

4.Methods of installation

Though the fan and the motor has proofread before leave factory, you should proofread again after the fan will installed on the base because of transit and the flexible distortion of the base per se.

1.Emendation

In principle, the fan plane takes benchmark with shaft, but when the axile fan will be installed by standing type, the plane also takes benchmark with cover of V-belt or impeller hub.

Check the plane with gradienter after park the fan on the smooth concrete base, calibrate the plane with gaskets among the fan and the base, then fill the grout. At the same time, fill the grout into the prepared bolts holes beforehand, and fixup the bolts vertically.

Tighten the basal bolts equably, or else will lead excursion of the shaft center and scathe of the bears.

In this connection, you’d better think about exchange bearings expediently and don’t take down the fan try your best.

Set up window or door for inspecting and exchanging bearings.

If the fan is installed with spring damper, the balanced height requirements in Sheet 1 shall be reached: unit: mm

|

Chassis Length L |

≤2000 |

>2000~3000 |

>3000~4000 |

>4000 |

Notes |

|

Tolerance |

3~5 |

4~6 |

5~7 |

6~8 |

Balanced Tolerance |

|

Note: The height of loaded damper shall be in same, and only loaded with vertical force, without any tangential or torsion force. |

|||||

2.Installation of bearing box

You should notice the axile direction power has no effect to the bearings when tighten all the bolts.

Using of bearing house

Tighten the bolts where on the bearing house according to drawing 8. After tighten the bottom bolts, for the plane midsplit bearing house, first tighten the free side bolts slowly, usually, we take the motor side as the fetterless side, for the hot fan and the fan driven by type E also choose the side hasn’t motor, then tighten the bolts at the fetterless side.

Must think about expanse of high temperature fan.

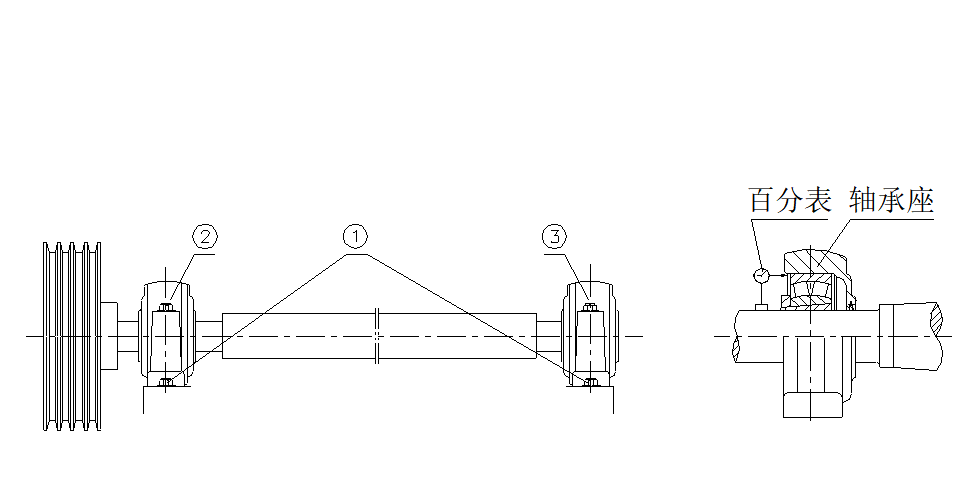

Methods of emendation of shaft and bearings

Drawing 8 Drawing 9

Put down the lateral cover, load a centesimal watch, take the determine point with periphery of bearings(if it is impossible, take the side of bearing house). Turn the shaft lightly, and then read and mark the largest and smallest value. Then we get the wiggle value T, this value equals up and down value minus right and left value. If the distance from test point to axes is R, T divided R equals gradient value.

The allowable gradient value for double-row self-aligning roller bearings and ball bearings is different depending on the size and loading condition. Under normal loading condition it shall be between 1.5o~ 2.5o. Whether this setting value can be reached, is depending on the bearing configuration design and sealing models.

Using of bearing

Though the bearings have 2°adjustable range with its automatic performance, you’d better pay attention to installation because the bracket of this unit is too simply:

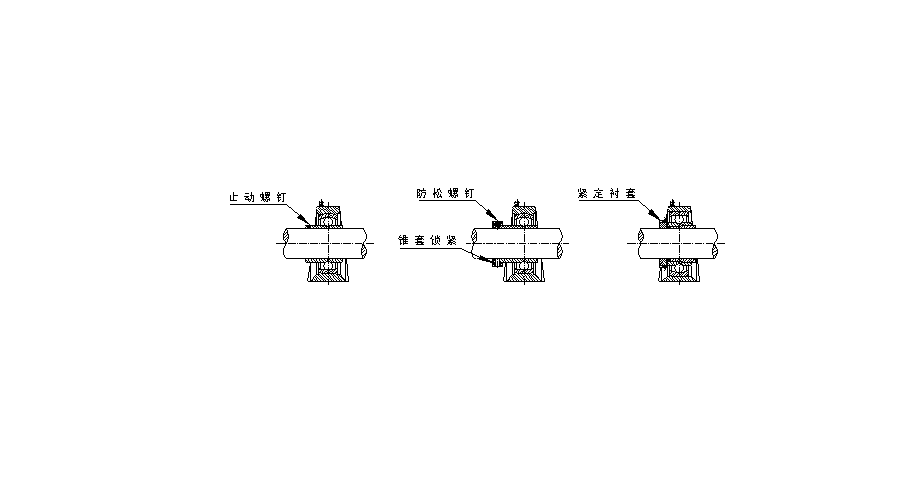

Unit of bearing with stop moving bolts

Make a bore and orientation after adjusted the distance between bearings. The orientation position holes must as same with request. You should pay attention to start and change of the bolts day-to-day. Otherwise brings opposite sports between inside cover and bearings. See drawing 10.

In wedge principle, purpose of to fix the bearings on the shaft is good. Put the eccentricity ring on the lengthen part where with eccentricity, then tighten it. At the same time, notice the bolt. See drawing 11.

Drawing 10 Drawing 11a Drawing 11b

It uses tight position bushing to reach a tight fitting among bearing, bush and axle. During installation, please pay attention that when the bearing is pressed onto the conical bush and round screw nuts are tightened, radial movement will be arose and the radial inner space of bearing will be reduced (drawing 11b). We recommend you let experienced technician using hook wrench to tighten these nuts.

3.Notarize the direction of motor

Notarize no abnormity when install the motor.

Notarize the direction of motor is correct before hang on the V-belt or install the shaft joint.

≤0.15~0.20mm Radial error b≤0.15~0.20mm

4.V-belt and pulley

Check the V-belt and pulley before the fan startup, revise the center between two pulleys and adjust the strain of V-belt.

See the sixth chapter about maintenance and checking of belt wheel and V-belt.

5.Shaft joint emendation

When install the fan driven by shaft joint, the emendation with shaft joint. At first demount the bolts, put down the pin, turn the flange trays, checking the windage at the same time. In common, usually, the windage range has shown in drawing 12.

6.Join of pipe

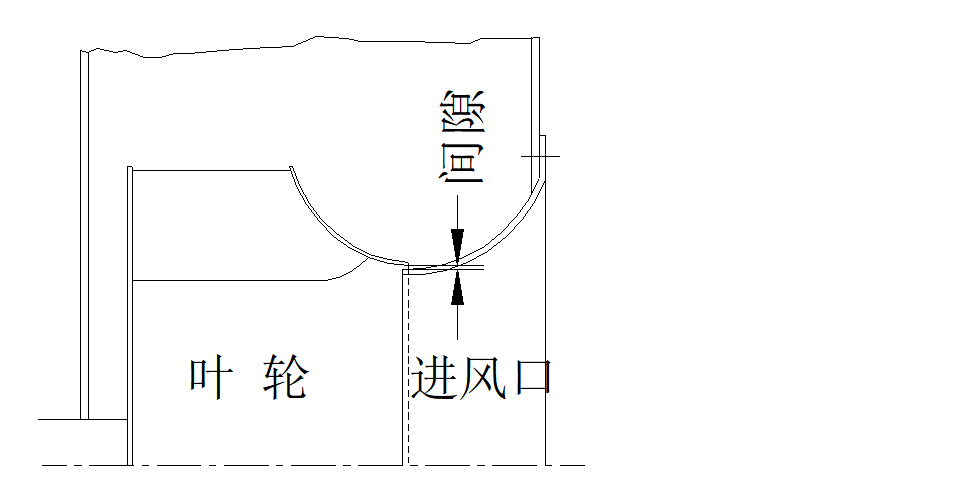

The fan are joined with flexible pipe, tighten the bolts equably, get the consistent center, otherwise, anamorphic casing will arouse attrition between inlet and impeller.

Check the fan inside before join, must clean out the eyewinker.

Set a safety net with enough intensity on the inlet when the fan will not be jointed with pipe.

At the end of installation, check the clearance between impeller and inlet, ensure the clearance is symmetrical and consistent. See drawing 15

7.Installation of hot-air blower

To avoid the effect of expand with heat to the fan.

1.Joint of inlet and outlet

Must use the inflatable tie-in, the heat stress is not charged with fan. For the armor plate structure pipe, the temperature changes 100℃ every 1000mm, the volume of distortion is about 1.3mm. See drawing 13.

Poor Good

Drawing 13

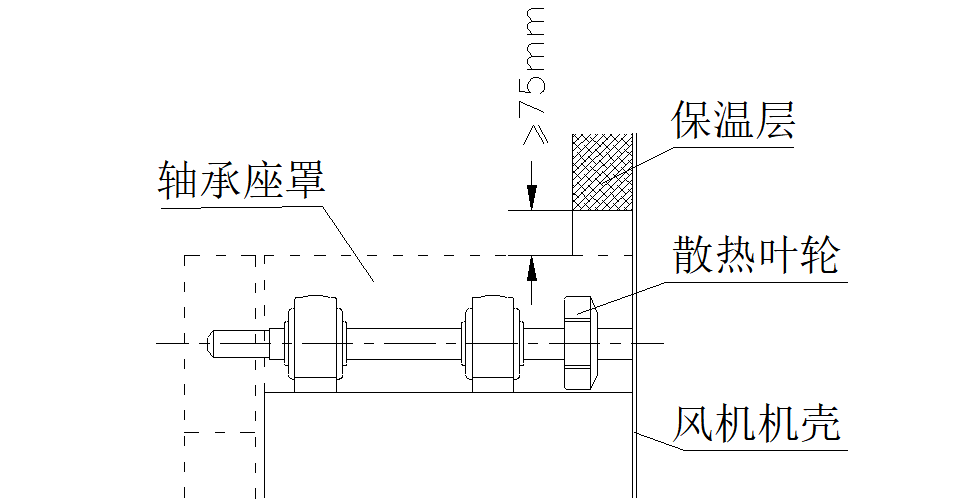

2.Cooling of bearing

For reduce the effect of medium temperature, install a exhaust fan (for the gas temperature less than 250 ℃). And don’t wall up the outside of the fan. See drawing 14.

Drawing 14

Drawing 15

5.Commissioning

The process as follows:

Check

Tighten each bolts and nuts equably, or else arose noise, libration, air divulgence and abrasion of bearings and shaft.

Put on steam

The bearings has put on suitable lubricant, if you want put on again, must insure the quality of lubricant.

Put on steam according to the direction.

Please see the sixth chapter for replenishment of lubricant.

Jigger

Please pay attention to follow when turn the impeller:

listen the sound

If the sound listens unusually, please notice.

other

The stretch of V-belt.

The feeling is too weightily of jigger.

Air-feeding system

All the parts are meet the demand.

Eyewinker near the in-outlet or in the fan.

When running, if there’s insecurity around the in-outlet.

Electric fittings

Insure there’s no open circuit in the system.

Go over the connection in the junction box.

Startup

Startup after insured the order of fan system, electric system and other machines. Turn on the switch, turn off after 3~6 seconds, insure the turning, libration and sound are correct.

In this instantaneous running, examine and repair according to forward narrate if there’s abnormity, then startup again.

The electric current has 5~7 times to rating electric current of fan ad motor when startup, then debase gradually. If the electric current will debase very slowly, you should check the electric system.

Notarized the running

If necessary, open or close the adjustive door slowly after you got the value on the amperometer.

Mark the electric current and pressure

Check the libration, temperature and sound of bearings.

During a week from the fan startup, please pay attention to the follows:

Friction of rotors

Between impeller and inlet

Between impeller and casing

Between shaft and casing

Between V-belt and belt cover

Fettle of V-belt

Check the balance of V-belt

Strain of V-belt

Abrasion of V-belt

Swing of shaft joint

Deflection of foliose regulating valve.

Other

Inhalation of eyewinkers

Libration of fan self

After test run, shut down the system to adjust the V-belt.

Check the bearings with its lubricator withal.

For the high temperature fan without jigger, shut down the system when the inside temperature reduce to100℃。

The performance can not be changed through increase rotate speed. Otherwise brings accident.

Maintenance and management

The inspection split into periodic check and daily check. You’d better pay attention to the part of transmission in daily check.

If the fan runs placidly during running-in, eriodic check according to sheet 2 for a 2~3 weeks distance.

|

check part |

item |

content |

|

meter |

amperometer

voltmeter tachometer |

Whether the meter has abnormity?whether the vision has abnormity? |

|

casing

|

shake | Whether the bolts become flexible?Whether the jointing with surface and frame was collapsed? |

| blowby | Whether the seal was destroyed? | |

|

casing |

shake | Whether the bolts become flexible?Whether the jointing with surface and frame was collapsed? |

| blowby | Whether the seal was destroyed? | |

|

impeller |

Rub with casing | Whether the clearance in inlet is equality?Whether the clearance with casing is equality?(axial fan)

Whether the motor keeps plumbed with casing? |

|

impeller |

shake |

Whether the dust accumulated badly?unbalance

Whether the bolts of hub become flexible? |

|

distortion of impeller |

Cauterization abrasion and distortion fearful | |

|

distortion of impeller |

Whether the part of installed bearings and the bearing cover were destroyed? | |

|

bearing bearing house |

shake, heat, noise

|

Whether the bolts and gaskets become flexible?Whether the bearings were damaged?

Whether the oil leaked? If the seal is excessive? Whether the lubrication is excessive and unclean? Check the noise with stethoscope. Whether the temperature is higher touch with hand and thermometer? |

|

base |

shake |

Whether the bottom bolts become flexible?Whether the base is good? |

|

pulley V-belt shaft joint other |

flap, heat |

Whether the belts are skid and attrite?Whether the pulleys are balanced?

Whether the keys become flexible? Whether the belt wheels are attrite? The strain of belt isn’t enough. The lengths of all belts aren’t alike. Whether the swing of shaft joint overrun the tolerance? Whether the fixed bolts become flexible?

|

The sheet 3 will show you to find out the faults easily.

Sheet 3 Trouble Shooting

|

fault |

reason |

Measurement |

|

Volume too small |

static pressure designed too small

pipes air leak and resistance is too large adjustive door opened too small the turning is error the speed reduce because the skid of belts |

transvaluation of the design

adjust after inspection adjust put right in time adjust the strain of belts |

|

over loading of motor |

belts are too tight

mistake of motor choosen static pressure designed too large adjustive door adjusted bad faults of motor |

adjust the strain of belts

change reduce the rotate speed adjust again fix or change |

|

exceptional sound |

interfused rubbish:

crack or scar abrasion of the shaft friction of impeller locknut of bearings become flxible shaft shake bad pip system fan type is false the airflow flow gaspingly joints of pipes are bad |

change

change change tighten the bolts tighten the bolts again find out the reason and fix rebuilt the system or choose fan again adjust over again |

|

exceptional sound |

interfused eyewinkers

air volume is too large |

remove

rebuilt the pipe sysytem |

|

temperature hoik |

bearing heat with faults

badness of installation impeller badness of balance excessive lubrication lacking lubrication and the lubrication type is false motor over loading, badness of isolation friction in sealed parts |

adjust crack or change bearing

adjust the center and tighten the fixed bolts revise the balance of impeller wipe off the spilth supply lipin, exchange new lubrication adjust the load, repair isolation adjust or install again |

|

libration |

base intensity is not enough

badness of design the bottom bolts become flexible imbalance of impeller damage of the bearings abrasion of the shaft skid of belts effect from outside libration the swing of shaft joint overrun the tolerance the fan type is false |

reinforce, improve

tighten clean the impeller, revise the balance exchange exchange adjust the elasticity use the shakeproof gasket emendate again choose again |

Remark: these sounds should be estimated by the technicians has abundant experience.

Usually, faults of fan are noise, libration and hot temperature, therefore, daily check is important.

Libration

With the center line of motor and bearing house, determine and mark the libration value on X, Y, Z direction according to the standard JB/T8689-1998.

If the result is different to the standard, revise suitability.

We don’t hope the fan running less than the standard, even if the unspent fan recognized.

Sound

If the fan has exceptional sound, ensure the causations in time as follows: skid of belts, joints become flexible, eyewinker, bearings, motor. Especially check the bearings.

Please pay attention to the temperature of bearings house and casing. If you insist on 3~4 seconds when touch the surface, here and now the temperature is 60℃.

Motor’s running temperatures are different due to the isolation grade. The limited temperature of winding: grade B is 80℃ ,grade F is 100℃.

The belt wheels on the high side of temperature will arouse slippage of belt when the fan stopped. You should adjust the strain.

Maintenance and checking of bearing

Please refer to the stylebook about the bearing performance.

Please refer to this and the manufactory’s specification about installation and disassembly.

Natural life of bearing

According to bearing load, domestic and foreign standards, the natural life of bearings is 20000~30000 hours commonly beside special case.

Trademark, supplement interval, quantity of lube

If the common situation same with endure heat degree, see the sheet 4.Think over the trademark for high rotate speed and high temperature especially.

| lube

content |

domestic bearing |

imported bearing |

||||

| lubricating |

lubricating |

lubricating |

lubricating |

|||

| characteristic | common |

common |

high temperature |

common |

common |

high temperature |

|

standard mark |

GB443-89 |

GB7324-94 |

shell gadus s2 v100 2 |

GB443-89 |

shell gadus s2 v100 2 |

shell |

|

code |

L-AN46 |

2# |

R3 |

L-AN46 |

R2 |

R3 |

|

name |

engine oil |

Li fat |

Li fat |

engine oil |

Li fat |

Li fat |

supplement interval

In common, supplement according to the sheet 5. If in the execrable situation or the system runs continuously in 24 hours or runs in dust and aquosity, the supplement interval is half with sheet 5, also deploy a shield upon the bearings.

Infuse the lube slowly when the fan runs in low speed or jigger with hand.

Quantities of append lube are one third to half of bearing or bearing house cubage. Nimiety is adverse.

sheet 5 lube supplement interval for bearing and bearing house

|

running temperature of bearing (℃) |

r/min rotate speed |

||

|

≤1500 less than 1500 |

>1500~3000 less than 3000 |

>3000 over 3000 |

|

|

≤60 |

4 months |

3 months |

2 months |

|

>60≤70 |

2 months |

1.5 months |

1 month |

|

>70 |

the temperature rise per 10℃, halve supplement period (permit rising ≤40℃) | ||

open the bearing box to exchange the lube

In any case, open the bearing box cover to check one time every year at least. (Beside bearings

Are there any scars and cracks in the bearings?

Did the bearing brim tie in with bearing box well? Does the free part move normally?

Lube supplement of bearing box according to the oil lever line window(see the NOTE mark

In the center of shaft and bearing house, all the bolts and gaskets are tight.

Infuse the new lube after washed the bearings.

running temperature

The temperature about 40℃~70℃ on the bearing surface is natural, otherwise, when the temperature bigger than 70℃, must check it in time.

Maintenance and checking of shaft joint

Control the swing windage in request strictly

Replacing the worn pin in time.

Maintenance and checking of pulley l and V-belt

V-belt

The errors must in the allowable bound when the wheels have some slots.

Big length error affects the tiredness, libration and natural life.

Loosen the bolts where under the motor base, install the belts after you get a narrow center distance, if you prize the belts into the slots, the belts will rupture.

To reduce the natural life when the belts were stained with oil or dust, in particular oil.

The two axes must parallel, otherwise, the wear will be decline.

Please adjust the imbalance less than 1/3°. (See drawing 17)

Post time: Sep-27-2023